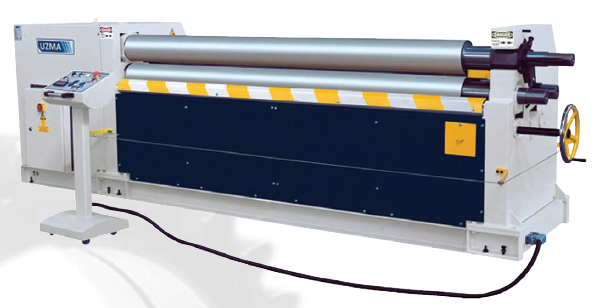

SPEED BEND PRO 2600-100

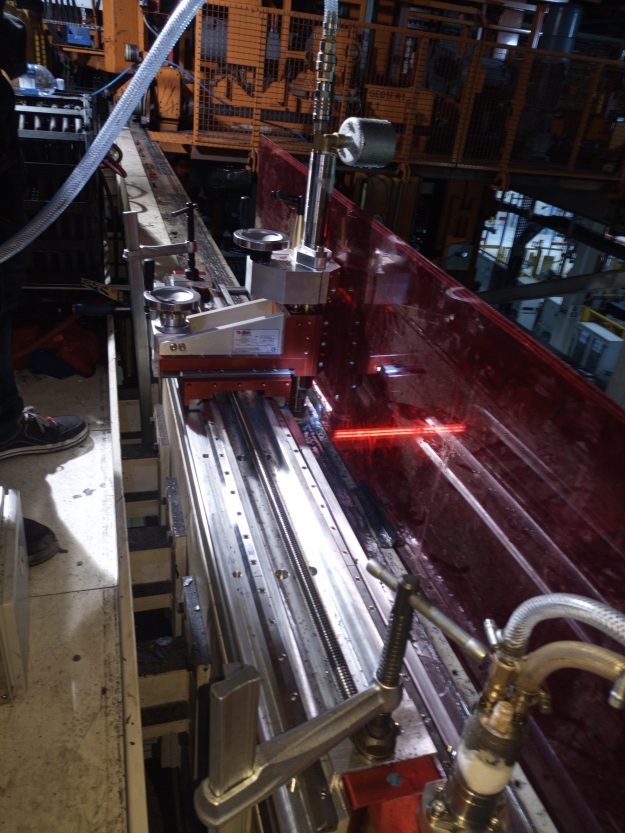

Company Metalo koncepcija increases capacity of machine park: it purchased a new hydraulic press brake. Bending capabilities: 100ton, 2600mm; Y1, Y2, X, R, Z1, Z2 axes; automatic compensation table; automatic height adjustment of the R axis; Delem DA-66T 2D Graphical control panel with touch screen; bending optimization system; laser Fiesler AKAS security system.

Lietuvių

Lietuvių